3D printing takes a giant leap

The concept of 3D printing has been in existence since the early 1980’s, with the technology used only by large corporations until recently when affordable entry level machines hit the market. The process allows 3D digital models to be brought into the physical world by applying the print material in layers until the structure is complete.

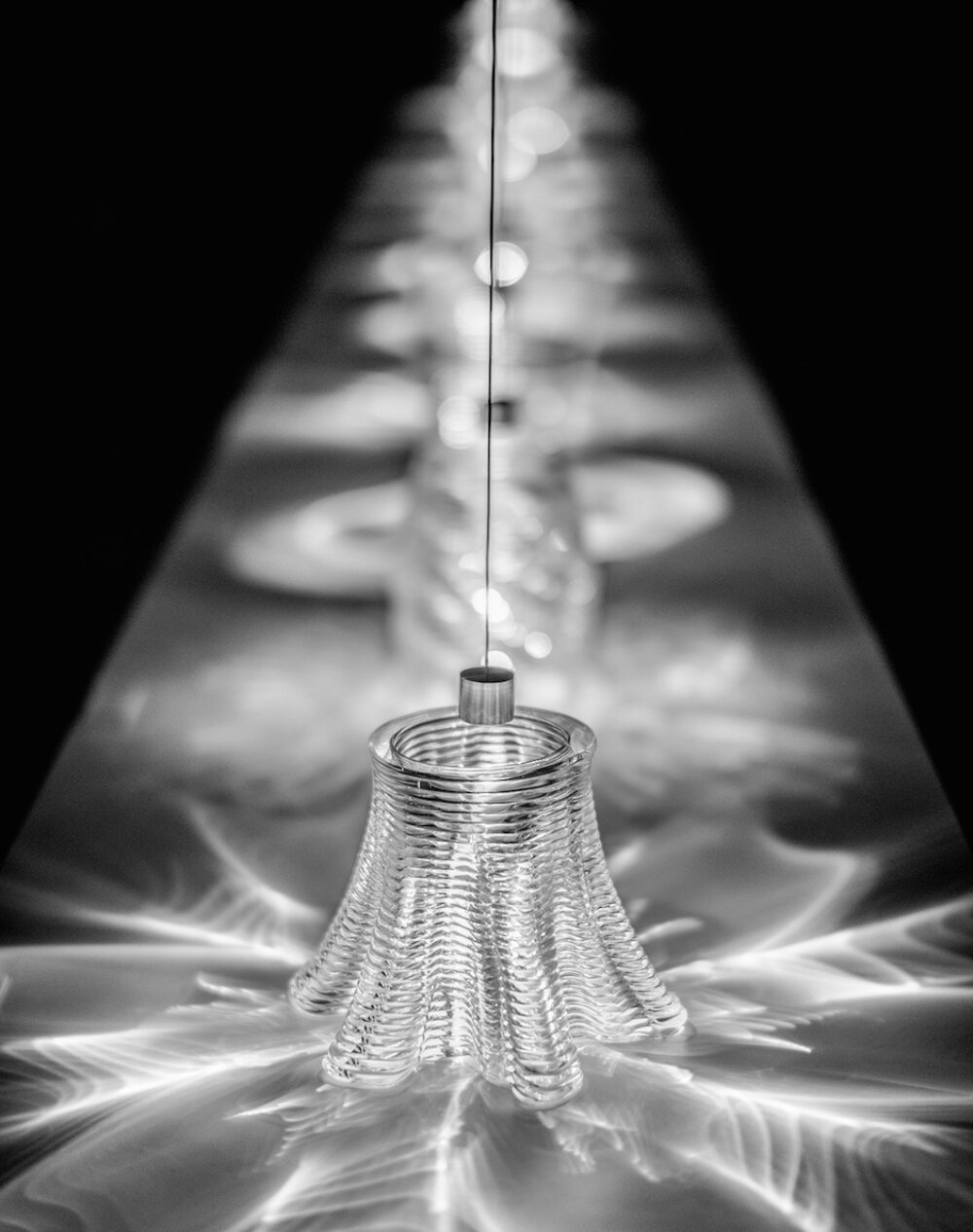

The materials used in 3D printing have largely been plastics-based, until now. Earlier this week MIT announced a breakthrough in 3D printing that could expand the application of this technology into new fields. A method called G3DP allows complex 3D items to be printed in glass.

Without getting too technical, the process uses two chambers, one to heat the glass and the other to melt the layers together. The result is a solid glass structure.

3D glass printing - Mediated Media

Although the technology doesn’t currently have any commercial applications, the potential is endless. It could revolutionise the way we use glass, from architectural applications to improvements in fibre optic cabling and the speed data is transmitted. Can you imagine how much faster internet speeds could be if 3D printed cabling was used in as part of the NBN roll out?

3D printing is still a very slow process and currently doesn’t compare to the modern manufacturing techniques utilised, regardless of the material used. However, this is a space to watch. As technologies improve so too will the capacity, efficiency and application of 3D printers. I believe we will be seeing many more breakthroughs with 3D printing in the near future.

Banner Image: WikiMedia

Profile Image: FibreFab

Gallery Image: Mediated Matter